HotKeywords: Sandpaper series ,

Classification of sandpaper

The particle size of sandpaper is graded based on the number of abrasive particles per square inch. The smaller the number, the thicker the sandpaper. Sandpaper is generally divided into 40 # -60 #, 80 # -120 #, 150-180 #, 220 # -240 #, 280 # -320 #, and 360 # and above. Processing with gradually finer sandpaper can remove the traces left by the previous coarse-grained sandpaper and leave a smooth surface effect. Commonly used particle sizes include 400 #, 600 #, 1000 #, 1200 #, 1500 #, and 2000 #. The reason why fine sandpaper is not directly used for polishing is because coarse sandpaper can quickly remove excess rough materials from the product, and then use finer sandpaper to polish it, which will make the surface of the product smoother.

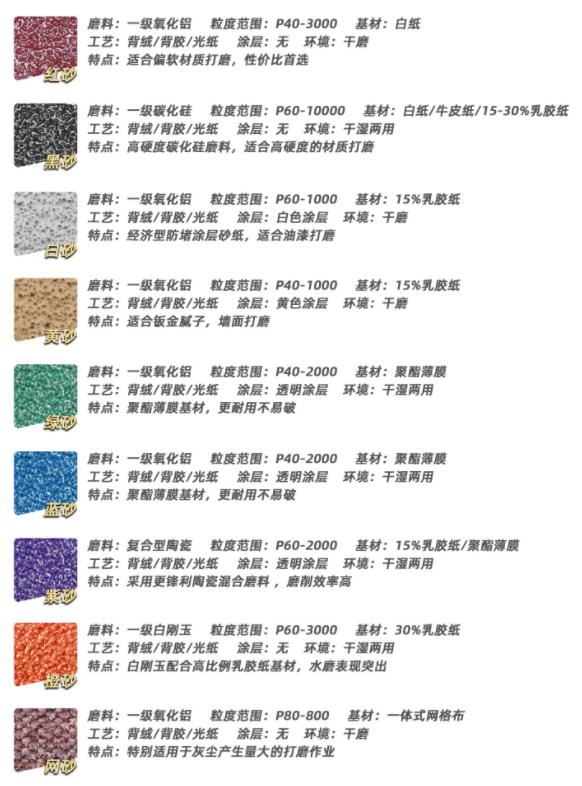

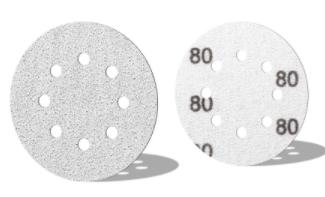

There are five main types of sandpaper to choose from, but not all sandpaper is beneficial for woodworking. Cellophane, also known as flint paper, is light in weight, usually light yellow. Cellophane is easy to decompose and seldom used for woodworking.

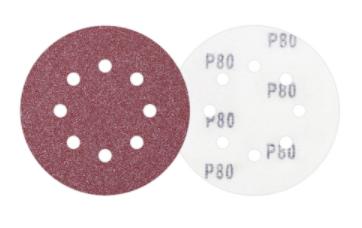

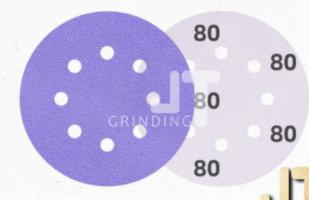

Aluminum oxide is another common type of sandpaper used in woodworking projects. It is the most commonly used paper type for electric sanding machines. Aluminum oxide is more durable than garnet paper, but it does not leave a good finish.

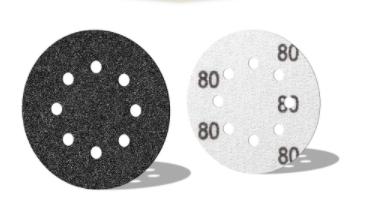

Silicon carbide paper is usually dark gray or even black. This type of paper is mainly used for precision machining of metals or for "wet grinding", using water as a lubricant. Although some advanced surface treatments use silicon carbide paper, it is usually not used for woodworking.

Ceramic

sandpaper is made from some of the most durable abrasives and can

remove a large amount of rough material in a short period of time. Ceramic paper is usually used for belt sanding machine belts, but sometimes it is also used for manual polishing of wood. It usually leaves a very rough surface, so be careful when using

ceramic sandpaper, especially on plywood or paint, as it can quickly

penetrate the finish layer and damage the work itself.

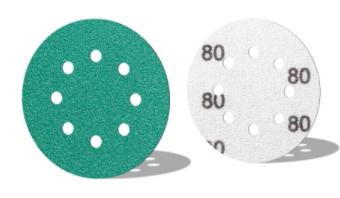

Polyester film sandpaper is used as a substrate for polyester film, which is more durable and not easily damaged. The surface is covered with a transparent coating, which can be used for both dry and wet purposes. It is generally used for polishing in fields such as aviation, ships, automobiles, composite materials, 3C electronics, etc.